Instructions for Automatic Powder Packing Machine

Dear users,

Hello. Thank you very much for using powder packing machine; For better use, please read this manual carefully before using.

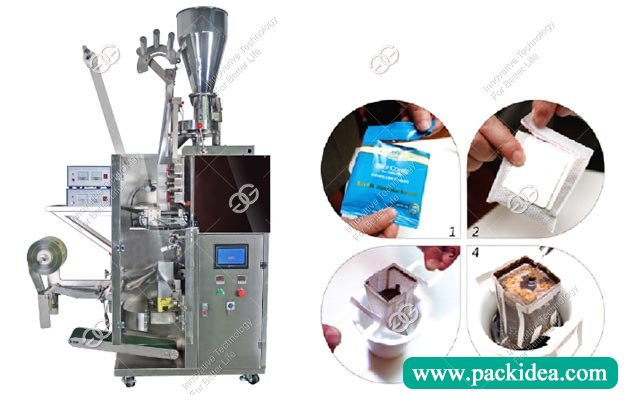

Performance and Purpose of Powder Packing Machine

This machine is improved with reference to foreign advanced new prototype, the use of advanced computer step structure control bag length, and rotary cutting, cooperate with photoelectric tracking, accurate, automatic bag making, measuring, filling, sealing, cutting, etc. The machine is equipped with high precision automatic thermostat to control the heat seal temperature, is one of the multi-function automatic packaging machines.

The machine has advanced structure, stable performance, reliable work, convenient adjustment and easy maintenance. The machine is suitable for small particles items and the powdery materials difficult to stick, such as cereals, sugar, monosodium glutamate, flour, rice flour, milk powder, medicine, chemical raw materials, tea, washing powder and so on measuring the packing of the item.

Main Parameters of Automatic Powder Packing Machine

1. Maximum bag size (length * width) unit MM: Length: 30-150 mm width: 20-140mm

2. Measuring range: 5~ 50g (with different diameter measuring cups), 3. Packing speed: 40~70 bags/min 4. Power supply: AC220V50Hz

5. Machine power: 1.8kw

6. Dimensions: 720*980*1680 mm

7. Packaging materials: polyethylene/nylon, paper/PE, polyester/aluminum foils/polyethylene, polyester/polypropylene

8. Packaging materials should be printed on the edge of the photoelectric control black mark, mark the width is not less than 5 mm is not less than 10 mm, long on the sideband with tags are not allowed to again with other words or logo, lest produce false action.

Preparation Before Use

1. Clean the box after opening the box;

2. Check whether the parts are loose;

3. Lubricating oil of various sports bodies;

4. Check whether the electrical circuit is abnormal;

5. Open an empty car test run, if there is a problem to be eliminated.

Maintenance for Automatic Powder Packing Machine

1. Before any maintenance, disconnect the power and prevent the machine from injuring the hand.

2. Always maintain the lubrication of various moving parts and add lubricating oil when necessary. After 150-400 hours of operation, replace the oil and replace it every 4000 hours.

3. Always keep the machine clean to prevent debris from falling into the hot seal mould or damage the gear in the gear.

4. If the electrical fault occurs, please check with professional technicians with experience of electronic circuit.

5. Always keep the sharp edge of the cutter. If you find that the incision is not in place, the blade should be replaced.

0086-15515573212

0086-15515573212